Ben Gribbin

October 21, 2016

Search

Popular Articles

8 Almost Useless Land Rover Mods

11th June 2014

Updated: What Makes a Defender Iconic?

29th November 2011

It's a common myth often spouted by owners and the press alike, everyone knows that the Defender makes use of the unique alloy, Birmabright in it's panel construction, right? The real answer is a little more complicated.

What is Birmabright?

Dutch Birmabright poster

Birmabright is the name given to an alloy made up of a proprietary mix of Aluminium, Manganese and Magnesium. The ISO designation of Birmabright is: AlMg2. It was created by Birmetals Co. of Birmingham in 1929. Birmabright was noted for it's excellent corrosion resistance and was used in the construction of light-weight boats and aircraft. Advantages of Birmabright include:

- Good finish

- Good formability

- Good strength

- Can be work hardened (e.g.., the metal is further strengthened by being deformed into panel shape)

- Excellent corrosion resistance (including marine applications)

- Resistant to stress corrosion cracking

In short, the perfect body panel metal!

Aluminium, because of the war?

I read an unconfirmed account once that contradicts the readily repeated story that Land Rover were almost forced into using Birmabright as it was in plentiful supply after the war and had fewer usage restrictions placed on it, unlike steel. Instead, a Land Rover magazine reported that Maurice Wilks had spotted a semi-submerged alloy boat on his estate, noting it's excellent resistance to corrosion. It was for this reason he selected BB for Land Rover panels. It just so happened that is was also relatively cheap and in abundant supply.

Earlier Land Rover models (Series 1 - 2) have thicker gauge panels, which is why often the body on older vehicles is still in great shape. This Birmabright was designated BB2, for it's two percent magnesium content. Starting with the Series 2a, Land Rover switched to BB3 (3% Magnesium) and panel thickness decreased. Then in 1980, Birmetals closed up shop.

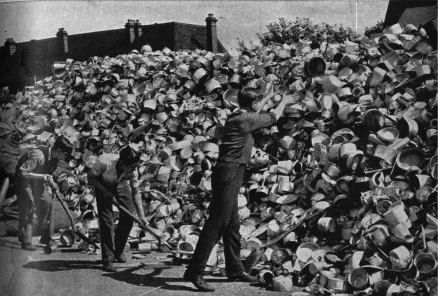

The End of Birmetals

Following a period of poor sales between 1977-1979, the company was listing. After 750 workers demanded a twenty percent wage rise due to inflation and then took strike action, the fate of Birmetals was cast and it ceased operation just a few days later.

This left Land Rover with the need to find an alternate alloy supplier for their vehicle bodies. In 1980, presumably after remaining Birmabright stocks were depleted, they switched to an unknown alloy, one that is much less corrosion resistant and a lot thinner. It is likely a form of NS4 / 5251 alloy and so from late Series 3 models onwards, Land Rover panels were most certainly not Birmabright!

Whilst other alloy manufacturers have experimented with the mix of Aluminium, Manganese and Magnesium, they have failed to replicate the original Birmabright. And now you know!

Need to replace your corroded Defender panels?

Related items for sale on eBay

| Ebay has returned a malformed xml response. This could be due to testing or a bug in the RSS2 Generator. Please check the support forums to see if there are any posts regarding recent RSS2 Generator bugs. CURL error code = 6. (Could not resolve host: rest.ebay.com) |

2 Comments

Leave a Reply

About Us

FunRover is a place for Land Rover enthusiasts to gather as a community and discuss the best 4x4 vehicles ever produced. We're building a library of high quality resources & articles to help owners along in their Land Rover ownership.

Popular Posts

8 Almost Useless Land Rover Mods

11th June 2014

Updated: What Makes a Defender Iconic?

29th November 2011

How to Plastidip your Land Rover Defender

19th August 2014

The BB poster is not dutch, it is danish. Thank you google translate ! 😉

Birmabright BB2 was simply a trade name for AA5251 which was made by many aluminium companies. Birmetals were absorbed into British Aluminium before closure and the trade name would have thus been acquired by British Aluminium who continued to supply Land Rover from their Falkirk plant with AA5251. Even Birmetals were beginning to refer to the product as AA5251 in their brochures of the late 1970s.