Ben Gribbin

October 25, 2017

Search

Popular Articles

8 Almost Useless Land Rover Mods

11th June 2014

Updated: What Makes a Defender Iconic?

29th November 2011

A while back, we published an article about the specific alloy used to make early Land Rover bodies, Birmabright.

One reader got in touch and shed a some light on the specific alloys involved in making Birmabright.

So what is Birmabright? Specifically BB2, as used on early Land Rovers? BB2 Birmabright is simply a trade name for the alloy AA5251 (in UK, HS4).

Chemical Composition of Birmabright (AA5251)

| Element | % Present |

|---|---|

| Copper | 0.15 |

| Magnesium | 1.7-2.4 |

| Silicone | 0.4 |

| Iron | 0.5 |

| Manganese | 0.1-0.5 |

| Zinc | 0.15 |

| Titanium | 0.15 |

| Chromium | 0.15 |

| Aluminium | Balance |

This alloy was made by a number of aluminium smelters. Birmabright was the name used by Birmetals Ltd (suppliers of BB2), who were bought out by British Aluminium and their parent company likely continue to own the trademark & rights to this day. British Aluminium continued to supply Land Rover from their falkirk plant until 2004. During the late 1970's, Birmetals brochures also referred to Birmabright by it's american standard name - AA5251.

Birmabright Properties

Description:

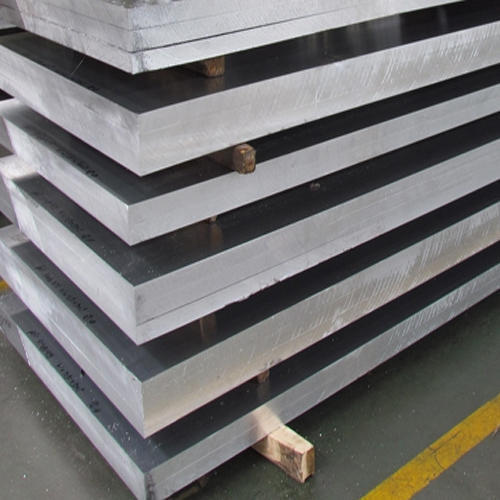

An alloyed non-heat treatable rolled aluminium sheet designed for general sheet metal work where higher mechanical properties are required together with a degree of formability.

Spec: BS EN 485-2:2008

| Physical Property | Value |

|---|---|

| Density | 2.69 g/cm³ |

| Melting Point | 625 °C |

| Thermal Expansion | 25 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 134 W/m.K |

| Electrical Resistivity | 0.044 x10^-6 Ω .m |

Sheet and Plate - 0.2mm to 25mm

| Mechanical Property | Value |

|---|---|

| Proof Stress | 120 Min MPa |

| Tensile Strength | 190 - 230 MPa |

| Hardness Brinell | 56 HB |

Welding Birmabright Land Rover Panels

All welding processes can be used on Land Rover body panels, including MIG and Tig. Recommended filler wire is 5356.

Location of Birmabright Works

Clapgate Lane, Quinton, Birmingham, circa 1945, credit Google. Note the camouflaged factory roof.

And the site today:

Other Brand names for AA5251

- Hiduminium 22

- Alcan GB M57s

- BA 21

- Alcoa 510

- AWCO 21

Related items for sale on eBay

| Ebay has returned a malformed xml response. This could be due to testing or a bug in the RSS2 Generator. Please check the support forums to see if there are any posts regarding recent RSS2 Generator bugs. CURL error code = 6. (Could not resolve host: rest.ebay.com) |

About Us

FunRover is a place for Land Rover enthusiasts to gather as a community and discuss the best 4x4 vehicles ever produced. We're building a library of high quality resources & articles to help owners along in their Land Rover ownership.

Popular Posts

8 Almost Useless Land Rover Mods

11th June 2014

Updated: What Makes a Defender Iconic?

29th November 2011

How to Plastidip your Land Rover Defender

19th August 2014