Search

Popular Articles

8 Almost Useless Land Rover Mods

11th June 2014

Updated: What Makes a Defender Iconic?

29th November 2011

1. Propshaft Maintenance

Whether you’re negotiating the most extreme off-road track in Europe or taking the other half for a serene Sunday afternoon drive, there’s work you can put in to prolong the life of your propshaft. The Universal Joints are the weakest part of your propshaft and need to be given regularly TLC. It’s hard to say how regularly you need to grease a UJ as it all depends on the conditions in which it operates.

If you’re driving through water, mud or on dusty tracks you will need to grease more regularly. If they are operating at a more extreme angle, they need to be greased more regularly. If you are putting a lot of power through the propshaft, they need to be greased more regularly. In fact, when you consider what you put these little fellas through; it’s no wonder they need a bit of care and attention.

2. When a Wide Angle Propshaft is needed

Before you make any crazy modifications to your Land Rover, say, a 4”lift, consider the operating angle of your propshaft. The optimum operating angle for a propshaft is 2-3 degrees and the further you stray from this, the more stress you put on your propshaft. Standard propshafts will stretch to 20 degrees when required but for the off-roaders out there this won’t be enough. The operating angle should always be kept as close to 2-3 degrees as possible but a wide angle propshaft can stretch to 30 or even 40 degrees (*40 degree propshafts are subject to application approval) in extreme circumstances.

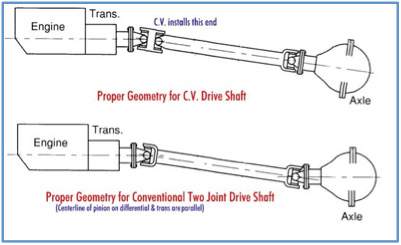

3.Double Joint Propshafts

A common misconception about double joint propshafts is that they are required whenever there is an extreme angle. This isn’t necessarily the case. A double joint shaft is only required when the flanges on your vehicle aren’t parallel with each other (see diagram above). Equipping yourself with this knowledge can save you money (as double joint propshafts are invariably more expensive than wide angle propshafts).

4. Propshaft Clearance

Another consideration is whether your propshaft will have enough room to operate. The propshaft requires plenty of room to operate at its widest section which is the where the universal joints fit. In addition to this, the tubing (diameter being anywhere between 50mm and 88.9mm depending on the length of you propshaft) will require enough clearance to curve slightly as it spins.

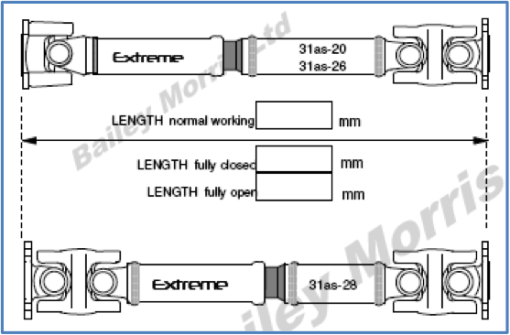

5. Measuring Your Propshafts

If the time should come when you require a propshaft you will almost certainly be asked what length you need your propshaft. The best measurement to take is a fully closed length from end of flange to end of flange. A specialist will also be able to use a “working length”. This is measured from end of flange to end of flange whilst the propshaft is on the vehicle free standing (you can also measure the gap between flanges if you don’t have a propshaft).

6. How to Break Your Propshaft

Nobody likes looking over the bill when you take your vehicle in for repairs; especially if it could have been avoided! Keep your propshaft fit and healthy by ensuring the following:

- Regularly grease your propshaft through all greasing points

- Monitor the angle at which your propshaft is operating (keeping it at 2-3 degrees if possible)

- Check that your propshaft is equipped to take the beating you will deal it by taking it off-road. Heavy duty universal joints, Rilsan coated spline section and wide angle components can all help.

- Check that the diameter of your tube is suited to the length of your propshaft – the longer the propshaft, the larger the diameter required.

7. Cutting Through the Jargon

Get clued up and convince your mates that you know what you’re talking about with these key terms:

- Universal Joint, UJ: The cross section comprising of bearing cups

- Flange: The propshaft component that bolts to the vehicle

- Spline: The internal sliding teeth of the shaft that allows the propshaft to extend

- Working length: The gap between the flanges on the vehicle as it sits on the road

- Closed length: The length from flange to flange as the propshaft is detached from the vehicle and fully compressed.

- Extreme Propshaft: The Bailey Morris brand of wide-angle and double jointed shafts

- Grease Nipple: The lubricating point on a propshaft

8. Ask for Advice

The single most important point I can make is that if you aren’t sure then ask for advice. It’s less embarrassing than asking for directions and we promise not to tell your wife! Our sales and technical team can help with most questions. Give us a call on 01480 216250, email on sales@baileymorris.co.uk or visit our website www.baileymorris.co.uk.

Related items for sale on eBay

| Ebay has returned a malformed xml response. This could be due to testing or a bug in the RSS2 Generator. Please check the support forums to see if there are any posts regarding recent RSS2 Generator bugs. CURL error code = 6. (Could not resolve host: rest.ebay.com) |

1 Comment

Leave a Reply

About Us

FunRover is a place for Land Rover enthusiasts to gather as a community and discuss the best 4x4 vehicles ever produced. We're building a library of high quality resources & articles to help owners along in their Land Rover ownership.

Popular Posts

8 Almost Useless Land Rover Mods

11th June 2014

Updated: What Makes a Defender Iconic?

29th November 2011

How to Plastidip your Land Rover Defender

19th August 2014

hello, do you supply propshafts for standard series land rovers, I’m looking for high quality rather than custom performance. If you do, may I ask how much. My vehicle is a series 2 swb with a standard 2.25 petrol. Thanks Rory