Ben Gribbin

October 8, 2015

Search

Popular Articles

8 Almost Useless Land Rover Mods

11th June 2014

Updated: What Makes a Defender Iconic?

29th November 2011

Here's what we've been up to over the last week.

We took the opportunity of perhaps the last bit of good weather to fit a weather sealing strip, should stop the dust blowing under the door in the hard winters we get.

Then we prepped the axles for painting, removing the shot blasting material from the inside of the axles - this would likely make an aggressive grinding paste if there were any left inside.

The shot used was an iron oxide of some sort and the internal surfaces of the axle were coated with the stuff. To remove it, we gave the whole lot a through wash with chassis detergent and a sponge.

Placing a scaffold pole through the axle tubes or even bolting some old stub axles on lets you easily rotate the axle on the stands.

The axles then needed drying completely, before using a solvent soaked rag to clean the internals and outside. The axles were then spotlessly clean, took an hour per axle though.

There will be no contamination of the diff oil now!

The diff studs were refitted, ready for the final drive casing.

The final drive casing mating surface after clean up to take RTV sealant.

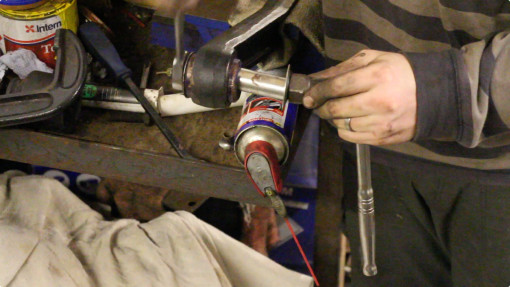

RTV applied, adding the bits before cinching those down and torqueing up.

After everything is securely sealed up, we can clean the diff casing - preventing the crud falling into the axle or onto the diff.

Then, the axles were solvent cleaned, etch primed, left to cure and finally painted in satin black

Whilst they dried, we began popping bushes back in. You can fiddle around popping them in with a vice or similar. We found it easier to secure the arm in the vice, then use a large M12 bolt with some thick washers to pull it through.

This would work really well if you had to do this at the roadside, a handy homemade 'tool'.

It can also be used to pull the inner race through

Related items for sale on eBay

| Ebay has returned a malformed xml response. This could be due to testing or a bug in the RSS2 Generator. Please check the support forums to see if there are any posts regarding recent RSS2 Generator bugs. CURL error code = 6. (Could not resolve host: rest.ebay.com) |

About Us

FunRover is a place for Land Rover enthusiasts to gather as a community and discuss the best 4x4 vehicles ever produced. We're building a library of high quality resources & articles to help owners along in their Land Rover ownership.

Popular Posts

8 Almost Useless Land Rover Mods

11th June 2014

Updated: What Makes a Defender Iconic?

29th November 2011

How to Plastidip your Land Rover Defender

19th August 2014